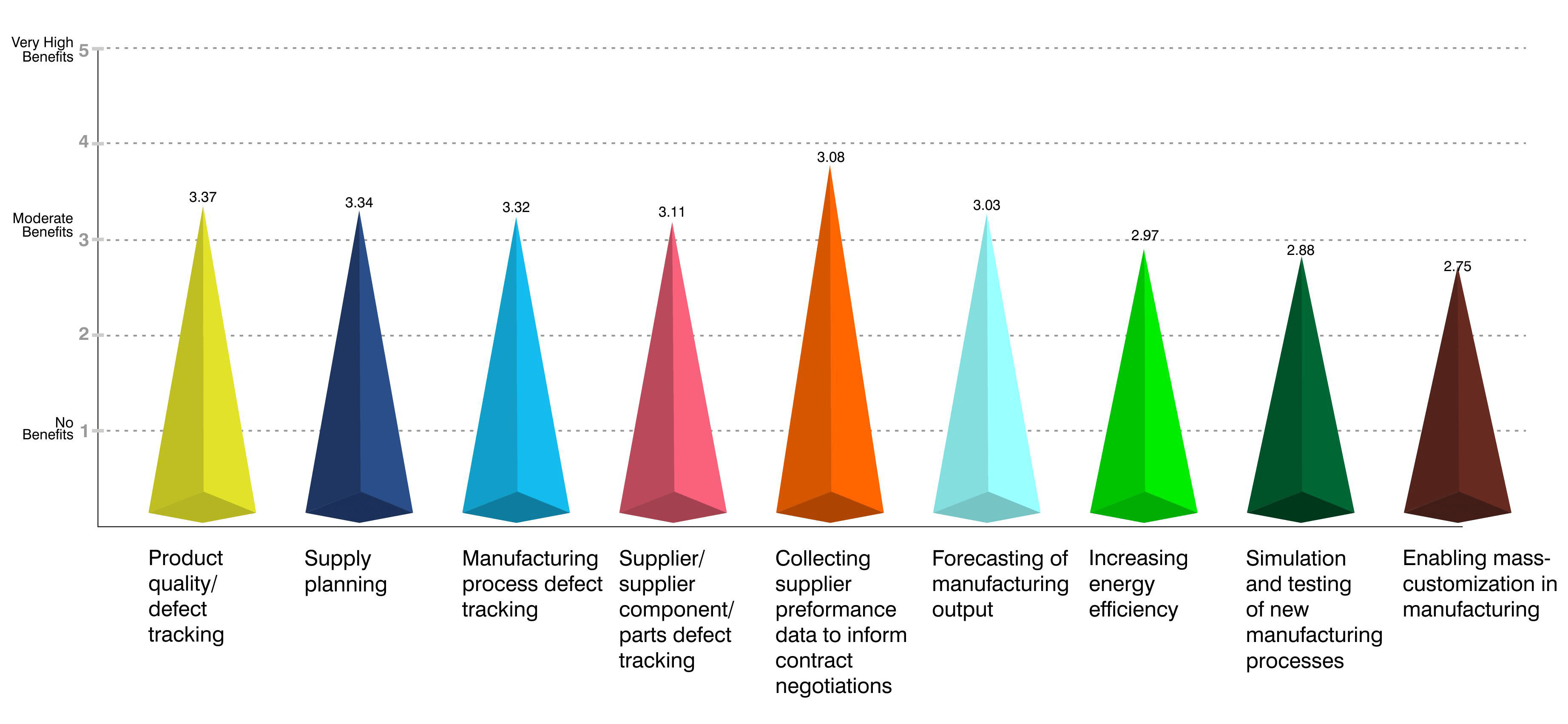

There’s no denying that Data has always been an important component of manufacturing, waste reductions, improvement in the efficiency and incremental profit gains. The inception of Big Data analytics is providing a new dimension to the manufacturing sector. From supply planning to growth in energy efficiency and the collection of supplier performance Data to inform contract negotiations, there is nothing that Big Data solutions can’t do which is evident from the graphic represented below. Data is grown up, with broader horizons and multi-dimensional capabilities. Big Data is unlocking myriad opportunities for the marketers to dive deeper into the historical Data in order to monitor production, network, and factory equipment.

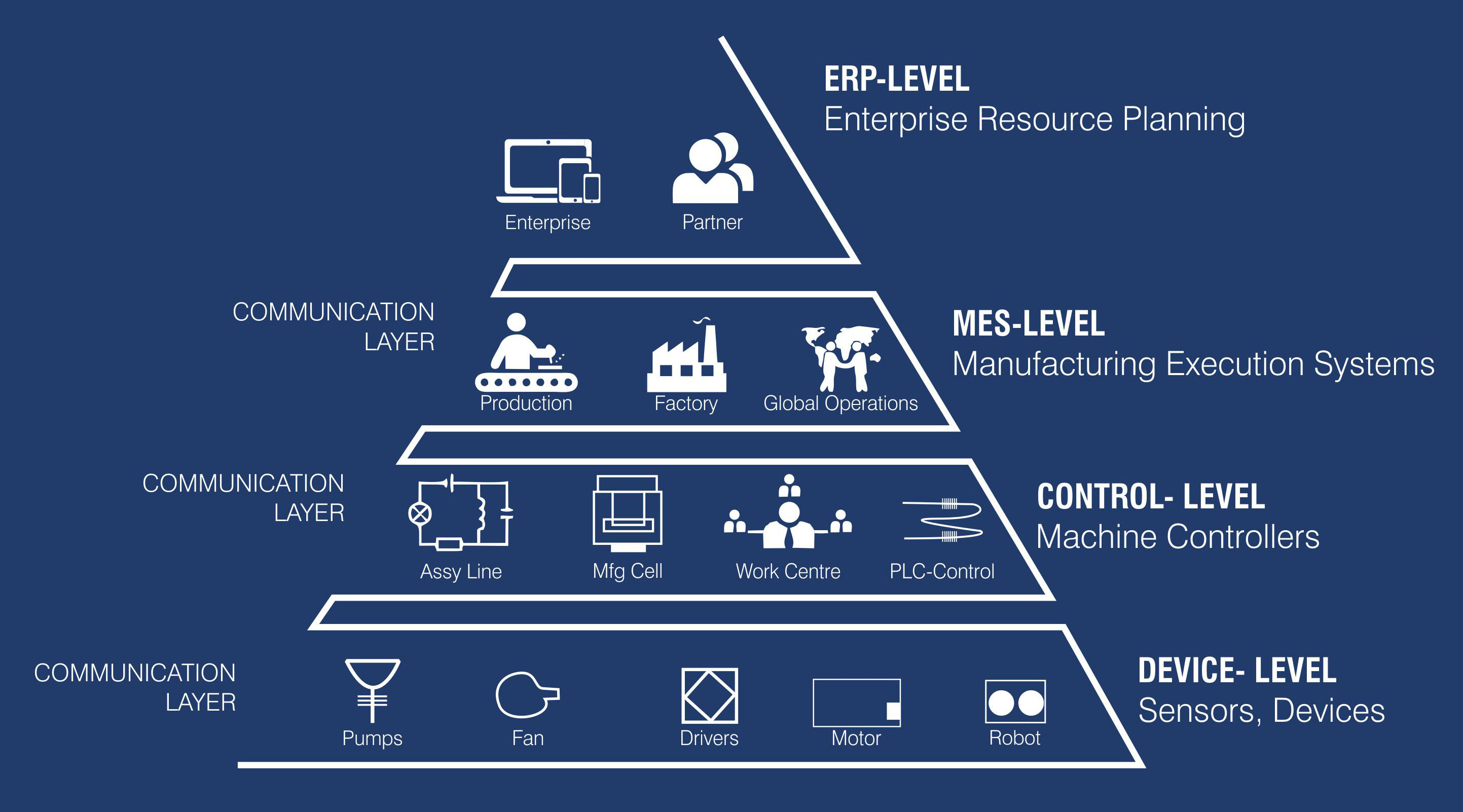

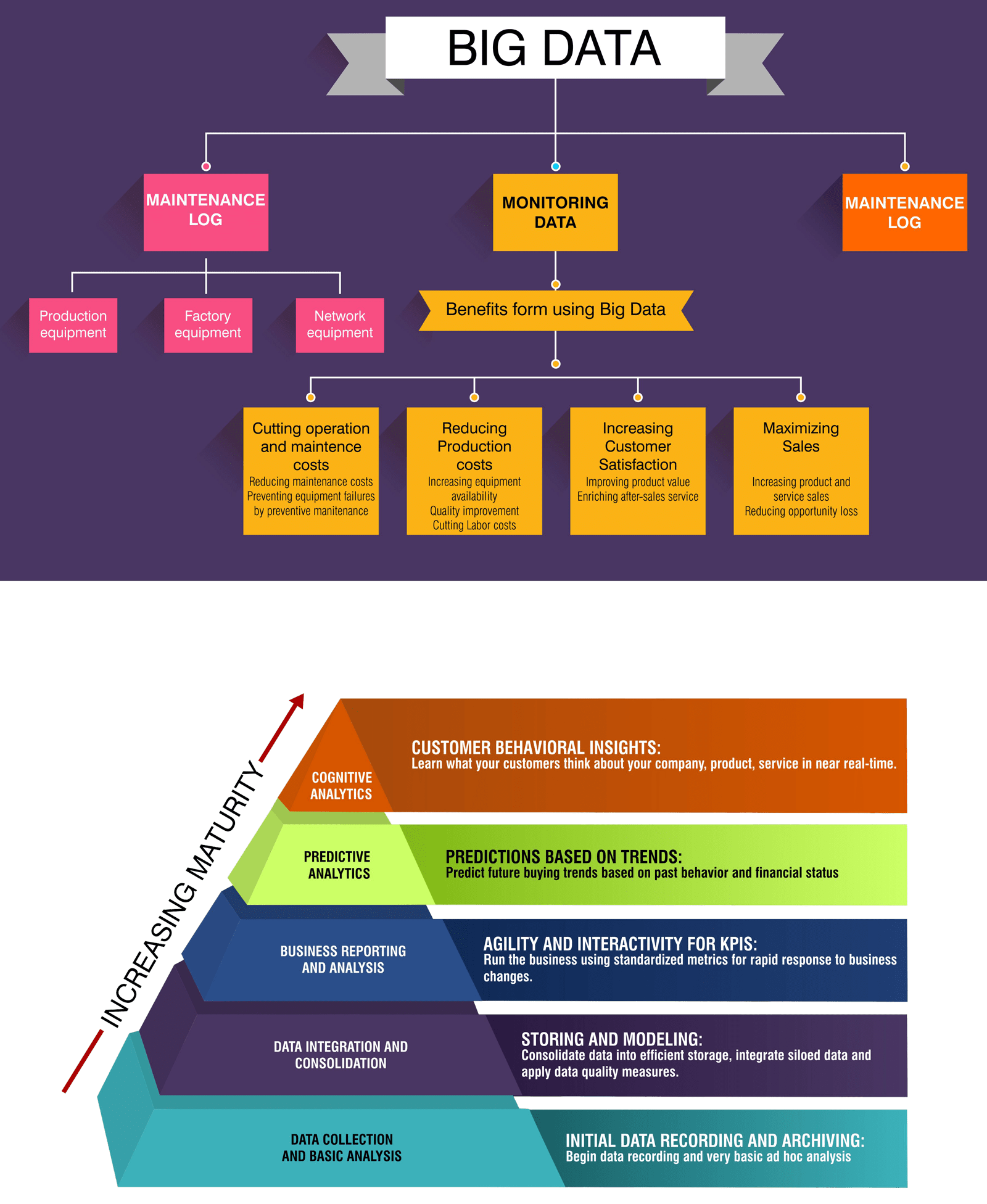

Monitoring Data in real-time can also help in cutting maintenance and operation costs, reducing production costs by increasing customers’ engagement and maximizing sales. Manufacturers in today’s scenario have a lot more resources for tracking and Data capturing than ever before. To convert Data into actionable insights, manufacturers follow the process that begins with the basic analysis of Data and goes through the Data integration, business reporting, and predictive analysis to reach cognitive analytics which later helps in deriving behavioral insights of the customers. For a better process, it also becomes imperative for the organizations to share and visualize information from level-1 (Device Level) to level-4(Enterprise Resource Planning Level). Here’s how manufacturing industry is leveraging benefits by using Big Data analytics in all the right ways.

Benefits From Using Big Data

Enterprise & Plant Topology